Golden diamond YB9320

Newgeneration PVD coating grade

General-purpose tool for turning and milling in avariety of materials

Unique atomic rearrangement technology for perfectintegration of coating hardness, toughness and thermal stability

Byadopting atomic rearrangement technology, long range orderly arrangement ofdifferent coating materials are achieved with perfect matching of hardness andtoughness, effectively solving the problem of high temperature instability ofmultilayer coating interface, improving the high temperature performance ofcoating

- Nanomultilayer coating with high toughness matrix and TiAlN substrate, unique ionetching technology, strengthening the edge, improving bonding strength betweencoating and substrate

—— Advancedsurface treatment technology, optimized stress distribution, superiorcomprehensive performance

Transmission high resolutionimages

Scope of application:

It is a general purpose insert, suitablefor turning and milling of a variety of materials.

It also can be widely applied in automotive, aerospace,mold and die, ship, IT, rail transport, engineering machinery, generalmachinery industryf.etc and semi-finishing and finish machining of small partssuch as small valves, pipe joint, decoration, etc.

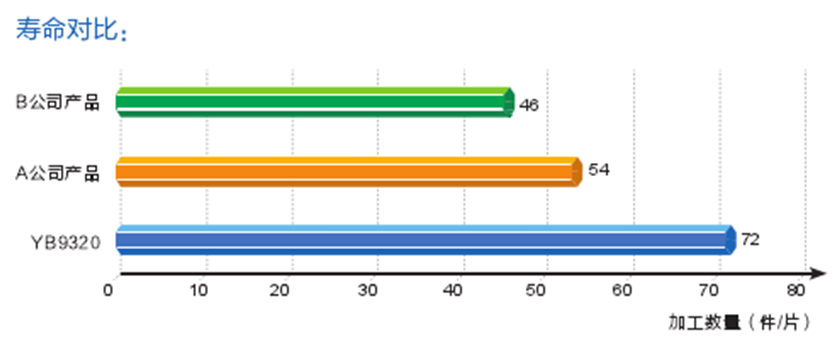

Case 1:

Cutting data:Vc=

Workpiece:flange (Φmax=

Workpiecematerial: stainless steel 316(HRC30)

Machiningstyle: external turning and end face turning

Machine:CNC machine

Insert:YB9320/CNMG120408-ADF

Lifecomparison

Product of CompanyB

Productof Company B

Machiningquantity(pieces/insert)

Result:Surface quality of ZCCCT product obviously superior to that of other companies,and tool life over 30% longer!

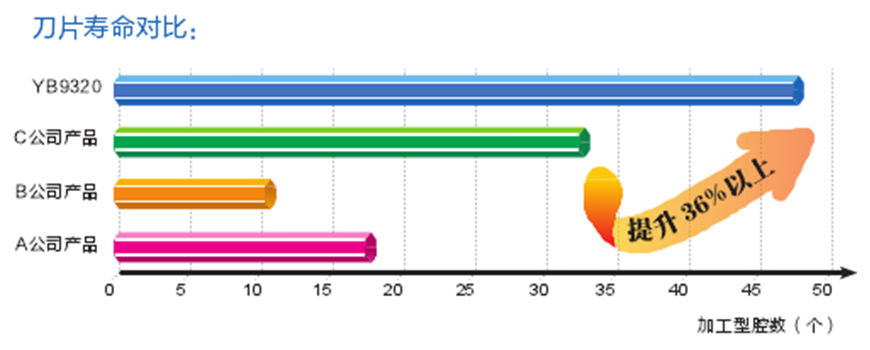

Case 2:

Cutting material: NAK80

Materialhardness: HRC28-32

Insert:YB9320/APKT11T308-APM

Tooldiameter: Φ16mm

Coolingstyle: Air cooling

Machiningstyle: cavity machining, layered milling 35*25*16 round corner R9

Cuttingdata: Vc=

Insert lifecomparison

Product of CompanyC

Product of CompanyB

Product of CompanyA

No. ofmachined cavity (piece)

Improvedby over 36%